Alumino Thermit Welding Kit

Thermit Portion

A Thermit Portion is a crucial component in railway maintenance, used for welding and repairing various types of rails. It consists of a mixture that, when ignited, produces extremely high temperatures, enabling the fusion of rail ends. This method ensures durable and secure rail connections, essential for the safe and efficient functioning of railway systems.

Pre-fabricated Dry moulds for all rail profiles

Pre-fabricated Dry Moulds are vital components in the railway industry, serving a crucial role in rail manufacturing and repair processes. These molds are precisely engineered to accommodate a wide range of rail profiles, ensuring that molten metal is poured accurately and efficiently.

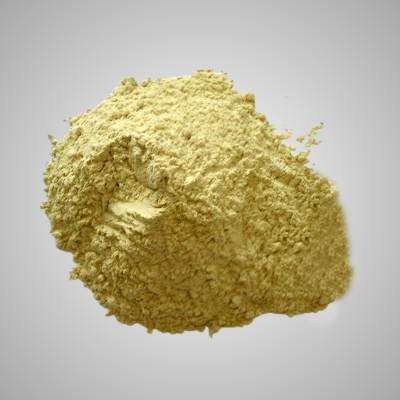

Luting Sand

Luting sand plays a crucial role in the thermite rail track welding process, where it acts as a protective barrier. During thermite welding, a chemical reaction produces extremely high temperatures to join rail sections.

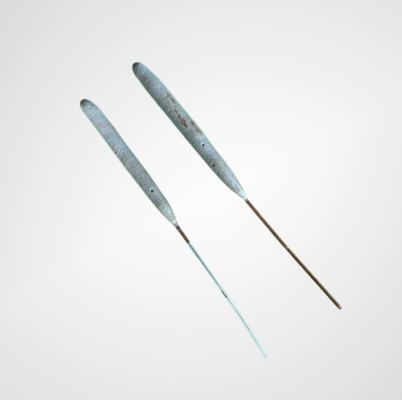

Igniter

An igniter is a critical element in the thermite rail track welding process. It serves as the ignition source for the thermite mixture, which is used to weld or repair rail tracks.

Auto Tapping thimble