Revolutionizing Rail Safety: Amiable - Leading Alumino Thermite Welding Manufacturer Supplier & Exporter in Bolivia

Amiable, established in 2012, has solidified its position as a renowned manufacturer and exporter of Alumino Thermit (AT) Welding Kits in Bolivia, a diverse range of Small Track Machines, and Ultrasonic Testing equipment for Rail/Weld applications.

Amiable has honed its core expertise in the field of Thermit Welding, becoming a comprehensive service provider. With a forward-thinking perspective and a problem-solving approach, we are the most dependable partner for ensuring the safety and reliability of railway tracks in Bolivia.

Our consistent growth is primarily attributed to our relentless pursuit of innovation, unwavering commitment to customer satisfaction, and the delivery of competitive solutions. These efforts have earned us the trust and confidence of our valued customers.

Unparalleled Rail Expertise: 50+ Skilled Professionals at Your Service

Amiable boasts a dedicated team of more than 50 highly skilled professionals strategically stationed across all 16 zones of the Indian Railways. This positioning ensures our readiness to tackle railway welding contracts and conduct Ultrasonic Flaw Detection (USFD) testing of welds with precision and efficiency.

Our proven track record in the industry speaks volumes about our capabilities. We are known for executing projects swiftly and efficiently, demonstrating our ability to meet the most demanding challenges in railway track welding and Ultrasonic Flaw Detection (USFD) testing. With Amiable, your railway projects in Bolivia are in the capable hands of experts who consistently deliver results, meeting and often exceeding your expectations.

Our Unparalleled Capabilities in Bolivia:

At Amiable, we take pride in being the leading Alumino Thermite Welding manufacturer in Bolivia. Our commitment to excellence is reflected in our proven track record, showcasing our capabilities in executing projects with precision and efficiency.

Our reputation for swift project execution sets us apart in the industry. We understand the urgency and importance of timely project completion in the dynamic landscape of railway track welding and USFD testing. Amiable ensures that your projects in Bolivia are executed with the utmost efficiency, meeting tight deadlines without compromising on quality.

Trusted Experts at Your Service:

When you choose Amiable as your partner in railway projects, you can trust that your endeavors are in the hands of experts. Our team brings a wealth of experience and knowledge to every project, ensuring that the solutions provided align with the specific requirements of the in Bolivia rail sector.

Exceeding Expectations:

At Amiable, exceeding expectations is not just a goal; it’s a commitment. We go the extra mile to deliver results that surpass your project requirements. Our dedication to excellence is evident in every aspect of our work, from Alumino Thermite Welding to Small Track Machines and Ultrasonic Testing equipment.

Alumino Thermit Welding Kit Supplier in Bolivia

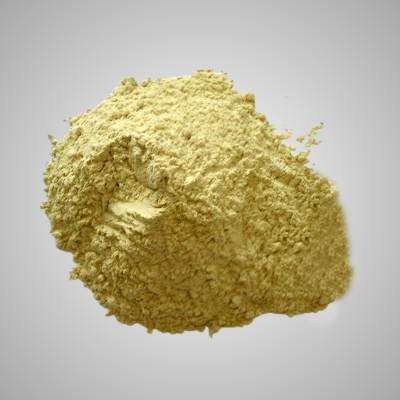

Thermit Portion

A Thermit Portion is a crucial component in railway maintenance, used for welding and repairing various types of rails. It consists of a mixture that, when ignited, produces extremely high temperatures, enabling the fusion of rail ends. This method ensures durable and secure rail connections, essential for the safe and efficient functioning of railway systems.

Pre-fabricated Dry moulds for all rail profiles

Pre-fabricated Dry Moulds are vital components in the railway industry, serving a crucial role in rail manufacturing and repair processes. These molds are precisely engineered to accommodate a wide range of rail profiles, ensuring that molten metal is poured accurately and efficiently.

Luting Sand

Luting sand plays a crucial role in the thermite rail track welding process, where it acts as a protective barrier. During thermite welding, a chemical reaction produces extremely high temperatures to join rail sections.

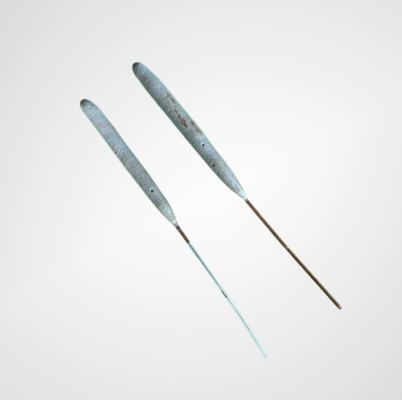

Igniter

An igniter is a critical element in the thermite rail track welding process. It serves as the ignition source for the thermite mixture, which is used to weld or repair rail tracks.

Auto Tapping thimble

Single Shot Crucible

The single-shot crucible is a pivotal component in various industrial processes, particularly those involving the melting and casting of metals in Bolivia. It’s designed to be a one-time-use crucible, offering exceptional convenience and efficiency. This disposable crucible eliminates the need for labor-intensive cleaning and maintenance, making it a preferred choice in applications where precision, cleanliness, and cost-effectiveness are paramount in Bolivia.

Long Life Crucible

A Long Life Crucible is an indispensable asset in the field of thermite welding, known for its remarkable resilience and performance under extreme conditions. Crafted from robust materials like graphite and refractory ceramics, these crucibles withstand temperatures exceeding 2,500 degrees Celsius, allowing for multiple thermite welding processes, reducing downtime, and ensuring the longevity and safety of rail connections. The precision-driven world of thermite welding finds reliable solutions with Long Life Crucibles in Bolivia, serving as a cost-effective and trustworthy option that guarantees optimal results for thermite welding processes. As a leading thermite welding manufacturer in Bolivia, we take pride in delivering crucibles that meet the highest standards of quality and performance.

Abrasive Rail Cutter

An abrasive rail cutter is a specialized tool designed for efficiently and precisely cutting railway tracks, making it a crucial instrument in rail maintenance and construction. It employs abrasive cutting techniques to sever rail sections cleanly, ensuring minimal disruption to rail operations and the safety of both workers and passengers. This tool’s high-speed cutting capability and durability make it an indispensable asset in the railway industry, where maintaining precise rail lengths and weld-ready ends is essential for safety and operational efficiency. If you are looking for a reliable thermite welding manufacturer in Bolivia, our company is a trusted provider of high-quality thermite welding services.

Compressed Air-pre Heating System

The Compressed Air-pre Heating System is an essential component in various industrial applications, especially in processes requiring high-temperature operations in Bolivia. This system uses compressed air to pre-heat materials or workpieces, ensuring they reach the desired temperature quickly and efficiently. Whether it’s for welding, forging, or heat treatment, this system plays a critical role in improving the overall energy efficiency of industrial processes in Bolivia.

By utilizing compressed air to deliver consistent and controlled heat, it enhances safety, precision, and cost-effectiveness in manufacturing and metalworking industries. As a leading thermite welding manufacturer in Bolivia, we strive to provide cutting-edge solutions for your industrial needs.

Weld Trimmers

Weld trimmers are specialized tools used in metal fabrication and welding processes in Bolivia. They serve the crucial function of precisely trimming excess weld material, ensuring the finished welds meet required standards and specifications. Weld trimmers come in various forms, including hand-held and mechanized options, and are highly valued in industries such as construction, automotive, and shipbuilding in Bolivia.

These tools not only enhance the aesthetics of welds but also contribute to structural integrity, making them indispensable in achieving high-quality, durable welds across a range of applications. As a leading thermite welding manufacturer in Bolivia, we understand the importance of precision and quality in welding processes.

Surface Grinders

A surface grinder is a powerhouse tool that comes into play as a critical post-welding solution, especially in the aftermath of thermite welding. These machines are meticulously designed to bring the welded joint and the surrounding rail surface to perfection.

They employ abrasive grinding wheels to methodically remove any protrusions, unevenness, or other surface defects. This process results in a smooth, uniform, and pristine finish, significantly enhancing both the aesthetics and the structural integrity of the track.

Pre-heating Torch

A pre-heating torch is a crucial tool in the context of thermite welding, a specialized method for joining or repairing railway tracks in Bolivia. The pre-heating torch serves this purpose by heating the rail ends to a specific temperature range just before the thermite reaction occurs. This controlled heating minimizes the risk of thermal shock, ensures the metal is in the ideal condition for welding, and prevents the formation of undesirable microstructures in the welded joint.

In addition to enhancing the quality of the weld, pre-heating torches also contribute to safety by reducing the potential for issues like rail cracking and misalignment. As a leading thermite welding manufacturer in Bolivia, we prioritize the use of advanced pre-heating torch technology to ensure the durability and reliability of railway track joints.

Amiable: Leading the Way as a Premier Thermite Welding Manufacturer in Bolivia for Rail Solutions

Amiable has earned a distinguished reputation as a trusted and highly commended provider of Rail Welding solutions across in Bolivia. The company’s extensive experience and expertise have led to groundbreaking innovations in the manufacturing of Thermic Casting Products, making it a leading thermite welding manufacturer in Bolivia. These products play a pivotal role in welding a diverse range of rail types and heavy metal machinery, employing the highly efficient SkV process, which can be executed both on-site and at the company’s own well-equipped premises.

Amiable’s journey in the rail welding industry, as a leading thermite welding manufacturer in in Bolivia, is marked by a commitment to excellence and a history of pioneering solutions. By producing top-quality Thermic Casting Products, they have significantly contributed to the advancement of rail welding technology in Bolivia. These products ensure the secure and seamless fusion of various rail types and heavy machinery components, making rail transportation safer and more efficient in Bolivia. Whether the welding process occurs at the company’s premises or at project sites, Amiable’s dedication to quality and innovation remains unwavering, solidifying its reputation as a leader in the field of Rail Welding solutions in Bolivia.

Aluminothermic Welding Process in Bolivia: Steps and Significance

Aluminothermic welding, a highly effective and widely used process, has gained prominence for its application in railway track maintenance. This welding method is crucial for ensuring the integrity and longevity of rail tracks across in Bolivia. Here, we delve into the Aluminothermic welding process and its essential steps.

Aluminothermic welding plays a pivotal role in railway infrastructure maintenance across in Bolivia. This process involves the exothermic reaction of aluminum powder with metal oxides to create molten steel, facilitating a seamless rail joint.

Steps Involved:

- Preparation:

- Rail Ends: The rail ends are thoroughly cleaned and prepped to ensure a contamination-free welding process.

- Molds Installation: Molds are strategically placed around the rail ends to shape the molten steel during the welding reaction.

- Ignition of Reaction:

- Aluminum Mixture: A precisely measured mixture of aluminum powder and metal oxide is ignited, initiating an intense exothermic reaction.

- Generation of Heat: This reaction generates extreme heat, reaching temperatures sufficient to melt steel.

- Pouring of Molten Steel:

- Controlled Flow: The molten steel produced is poured into the molds, seamlessly connecting the rail ends.

- Solidification: The poured steel solidifies within the molds, forming a robust weld.

- Post-Weld Inspection:

- Visual Examination: The welded joint undergoes a thorough visual inspection to ensure its quality and integrity.

- Ultrasonic Testing: Advanced testing methods, such as ultrasonic testing, are often employed to assess the internal soundness of the weld.

Significance:

Durability:

- Aluminothermic welding results in highly durable rail joints, crucial for sustaining heavy loads and ensuring the longevity of rail tracks across in Bolivia.

Reduced Maintenance Downtime:

- The efficiency of this welding process contributes to minimized maintenance downtime, allowing for continuous and reliable railway operations.

Safety Standards:

- The Aluminothermic welding process adheres to stringent safety standards, aligning with in Bolivia’s commitment to ensuring a secure railway infrastructure.

Cost-Effectiveness:

- While initial setup costs may be involved, the long-term cost-effectiveness of Aluminothermic welding makes it a preferred choice for railway authorities across in Bolivia.

Aluminothermic welding has become an integral part of railway track maintenance, ensuring the robustness and reliability of the railway network across the diverse landscape of in Bolivia.

About us

Amiable, established in 2012, has solidified its position as a renowned manufacturer and exporter of Alumino Thermit (AT) Welding Kits, a diverse range of Small Track Machines…

Get in Touch

Head Office

501-A, Surya Darshan Building,

Pai Nagar, J. S. Road,

Borivali West,

Mumbai – 400092, India